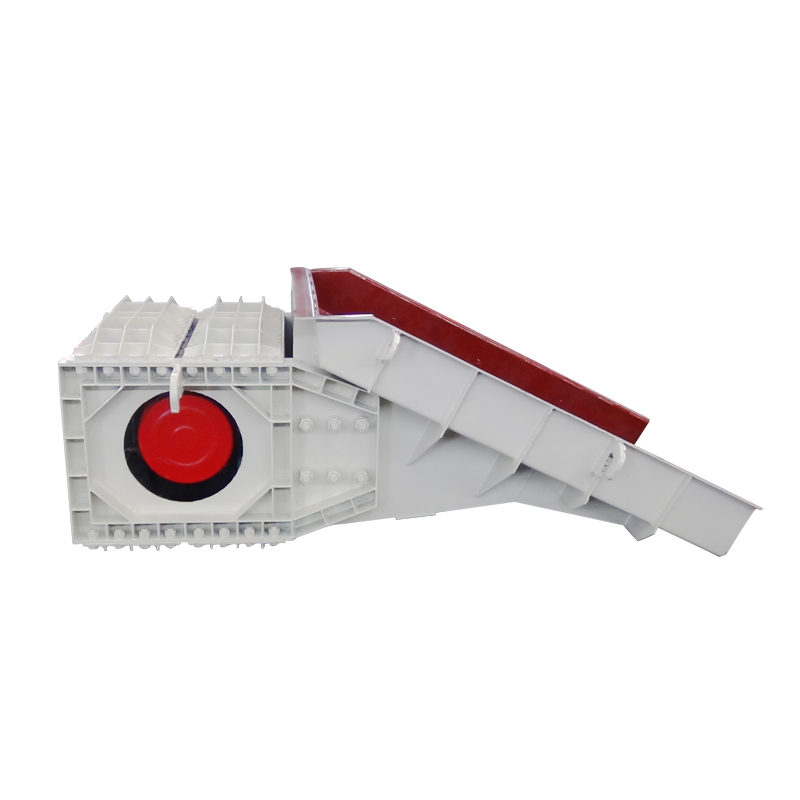

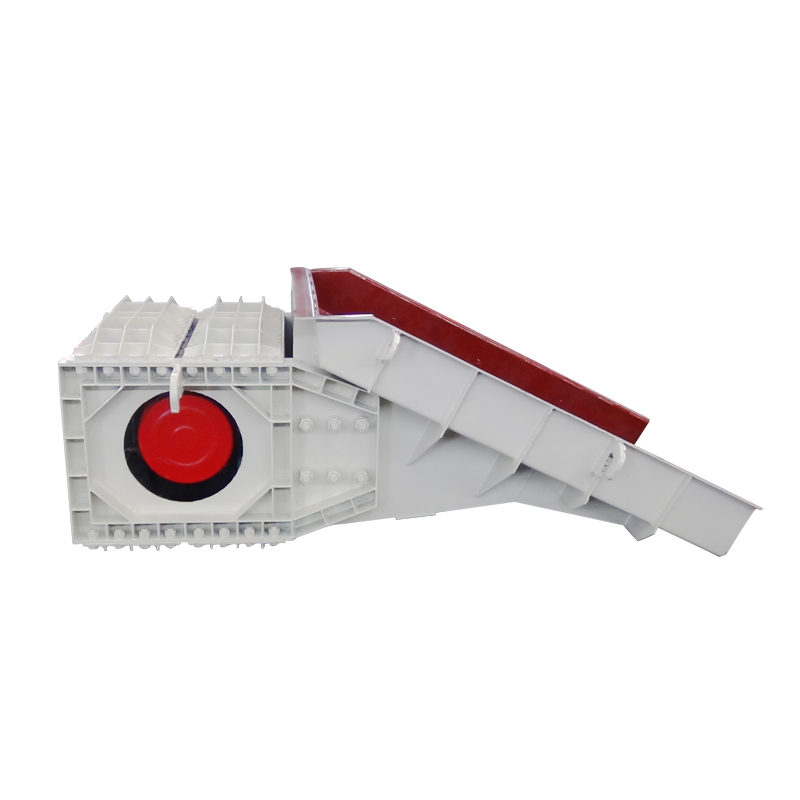

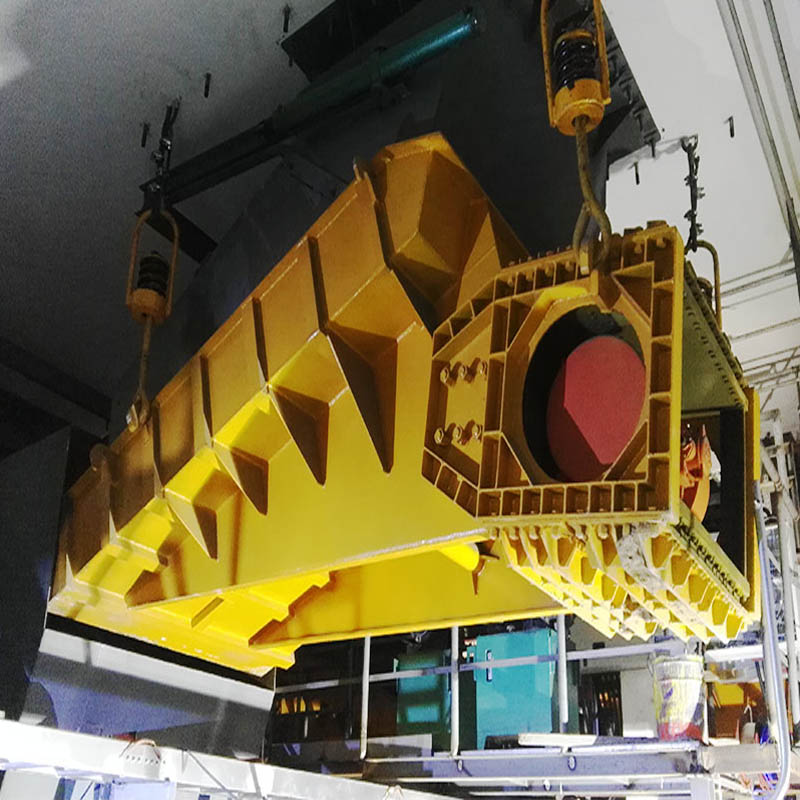

Double-mass vibrating feeder is also called vibration feeder,vibratory feeder or mining feeder. It is a kind of feeding equipment with advanced technology in the 1990s. It is a new product jointly developed by our company and Beijing General Research Institute of nonferrous Metallurgy and northeast Institute of Technology. In 1992, it carried out industrial commissioning in Dexing Copper Mine, Jiangxi province. In December of the same year, it passed the technical appraisal of Beijing Nonferrous Metals Corporation. In 1994, it obtained the new product certificate issued by five ministries and commissions of China.

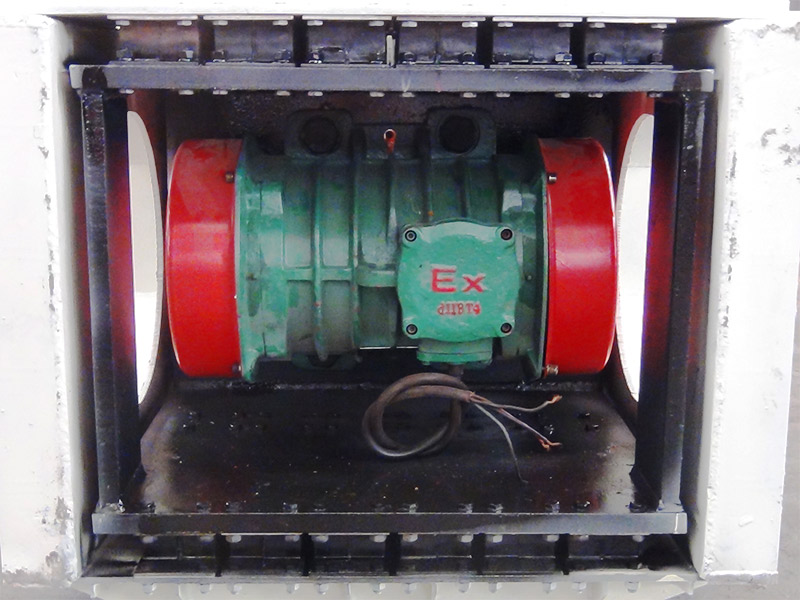

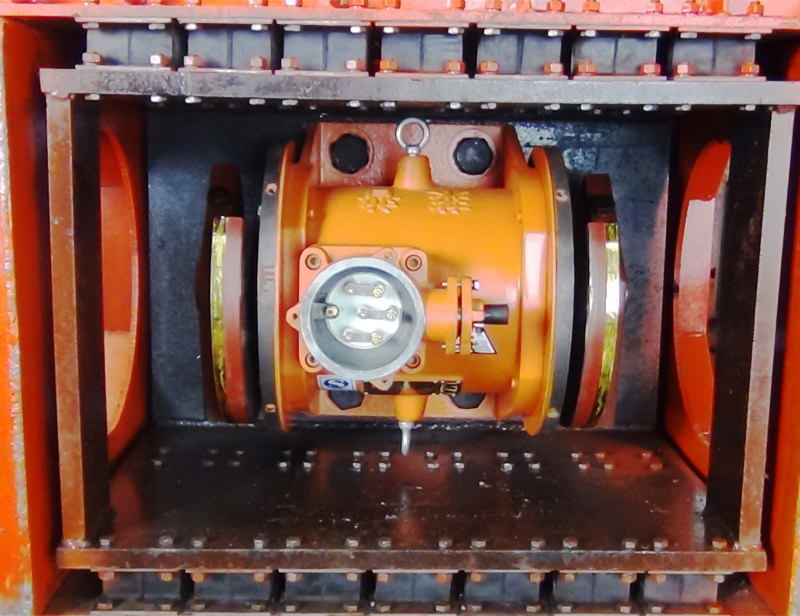

Double mass vibrating feeder is famous for its not burning motor, vibration motor installed in balance the shelves by the main vibrating spring is connected to a tub, through our rubber shear spring secondary to force, the main vibrating spring in vibration balancing planes and tub at work when the inertia force, the feeder under the condition of near resonance vibration, vibration force is small, can throw up the material sufficiently to reach the feed. It uses a “principle of parabolic type circular vibrating screen”, change the previous linear feeding way, in a quick rolling movement, reduces the tub of friction, avoid the tub too under dynamic stress and the transmission of bear too much force, longer service life, less energy consumption, low noise, smooth starting stop quickly.

In addition, the machine elastic force, electricity saving, energy saving, low noise can be applied to large feeding operation, and empty car can also be stable operation, can remove the worry caused by funnel emptying or stuck mine motor burn out, Improved production efficiency and economic benefits, and can meet the intermittent or continuous work requirements, even if no load or heavy load will not cause damage to the motor.

Double mass vibrating feeder has formed coal, metallurgy two series, widely used in metallurgy, building materials, coal, chemical industry, light industry and other industries to block, granular, powdery different material feeding system, in order to achieve continuous, uniform, automatic feeding. Best-selling national major coal mines, coal washing plants, non-ferrous metallurgical mines, power plants, grain stations, docks, loading station building materials and other places.

| Model | Figure Number | Groove Size (W×L×H)mm | Production Capacity(T/h) | Feeding Granularity(mm) | Vibrating Frequency(HZ) | Amplitude(mm) | Electric Current | Voltage | Power | External Dimension |

| (A) | (V) | (KW) | (W×L×H)mm | |||||||

| GLZⅠ240/1.5 | XZG6 | 900×1600×250 | 240 | <200 | 16 | 3.5 | 4.1/2.3 | 380/660 | 1.5 | 1092×2200×1640 |

| GLZⅠ350/2.2 | XZG7 | 1100×1800×250 | 350 | <250 | 16 | 3.5 | 5.7/3.3 | 380/660 | 2.2 | 1332×2400×1700 |

| GLZⅠ600/3.7 | XZG8 | 1300×2200×300 | 600 | <300 | 16 | 4 | 8.6/5 | 380/660 | 3.7 | 1556×2960×2100 |

| GLZⅠ800/5.5 | XZG9A | 1500×2400×300 | 800 | <350 | 16 | 4 | 12.5/7.2 | 380/660 | 5.5 | 1830×3500×2200 |

| GLZⅠ900/7.5 | XZG10A | 1800×2500×375 | 900 | <500 | 16 | 5 | 16.6/9.6 | 380/660 | 7.5 | 2500×3630×2400 |

| GLZⅠ1200/10 | XZG11A | 2000×2800×375 | 1200 | <500 | 16 | 5 | 20.5/11.9 | 380/660 | 10 | 2640×4030×2400 |

| GLZⅠ1000/5.5 | XZG9 | 1500×2400×300 | 1000 | <350 | 16 | 4 | 12.5/7.2 | 380/660 | 5.5 | 1830×3500×2200 |

| GLZⅠ1000/7.5 | XZG9B | 1500×2400×300 | 1000 | <350 | 16 | 4 | 16.6/9.6 | 380/660 | 7.5 | 1830×3500×2200 |

| GLZⅠ1300/7.5 | XZG10 | 1800×2500×375 | 1300 | <500 | 16 | 5 | 16.6/9.6 | 380/660 | 7.5 | 2500×3630×2400 |

| GLZⅠ1500/7.5 | XZG11 | 2000×2800×375 | 1500 | <500 | 16 | 5 | 16.6/9.6 | 380/660 | 7.5 | 2640×4030×2400 |