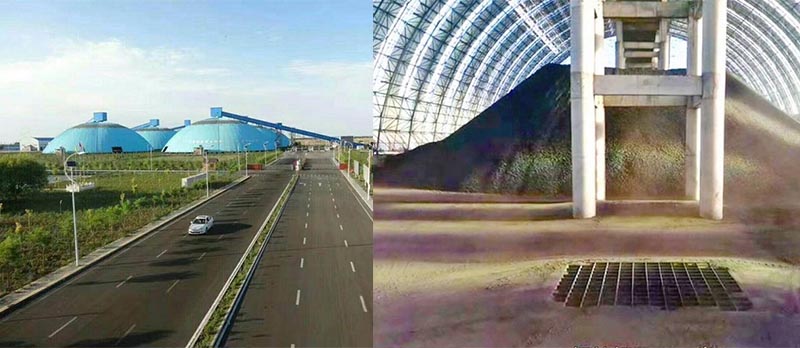

At the gathering station, the foreign coal is mainly unloaded into the large coal shed through belts or vehicles, and then fed to the coal conveying belt by the feeder below the coal shed, and finally transported to the express loading station for train or automobile batch outbound transportation. Coal transportation stations are the necessary consolidating and loading points for coal railway trunk lines. Without such supporting transportation stations, it is impossible to transport sufficient coal volume to the trunk lines. The coal collection station meets the needs of coal or foreign coal transportation in many small and medium-sized coal mines in the local area.

Under the coal storage shed of the consolidation station, the choice of the feeder is often neglected, resulting in great hidden dangers and waste of costs. Let’s compare and understand the advantages and disadvantages of different feeding products in different places.

Flat gates are relatively inexpensive, and feeding is done by opening or closing the gates, but there are many problems:

1. The gate opening is too large, and the coal self-flow feeding amount is large, which is easy to press the belt, causing the belt to spill coal and leak coal;

2. The gate is opened a little smaller, and the large pieces cannot come out, and it is easy to block the material.

3. Iron rods, steel rods, etc. are easy to fall directly and damage the pierced belt.

4. Uneven feeding and uncontrollable feeding amount

Compared with the gate, the reciprocating feeder has a relatively uniform and controllable feeding amount, which avoids the problem of the material directly impacting the belt. It has the following shortcomings since its use:

1. The shed is blocked. Because there is no activation effect during the operation of the reciprocating feeder, blockage often occurs, affecting the blanking and normal production. At the same time, the safety hazard of manual clearing is great.

2. Large amount of maintenance. During the operation of the reciprocating feeder, the problems of broken pins and broken cranks often occur. Due to the high-altitude operation and the narrow space of the coal conveying roadway, the maintenance and replacement are very inconvenient, the maintenance is difficult, and the production is affected.

3. The reciprocating feeding is a pile-like intermittent feeding, the feeding is uneven, and the feeding volume is small and the efficiency is low, which cannot meet the requirements of the fast loading station.

4. Coal leakage is serious. During the operation of the reciprocating feeder, coal is often leaked and sprayed at the bottom plate and the two side plates, the bottom plate and the back baffle, which affects the site environment, seriously pollutes the environment, and does not meet the environmental protection standards. Due to the poor ventilation and narrow space in the coal receiving tunnel, the coal leakage is not easy to clean, the coal powder is not easy to spread, and there is a serious hidden danger of dust explosion. The reciprocating feeder cannot be well sealed at the front and back and both sides, so the material leakage and ash leakage are serious, which is extremely unenvironmental.

This series of feeders often have oil leakage and bearing heating lock problems, which need to be inspected and repaired in time. The environment of the coal-receiving tunnel is harsh and difficult to overhaul, so the machine is not suitable for this occasion.

Belt feeders can feed uniformly, but they also have several disadvantages:

1. The belt is not resistant to smashing. It is very easy to break the belt when the material is often empty.

2. The sealing is not good like the reciprocating feeder.

3. It is easy to block the material and block the warehouse after filling.

4. The belt is seriously affected by the empty warehouse and continuous discharging. Each equipment needs to be maintained and inspected by post workers.

According to the special conditions and environmental characteristics of the coal receiving tunnel under the coal storage shed of the container transportation station, we recommend the patented product developed by Hebi Coal Chemical Machinery Co., Ltd., the dual-mass side discharge activation feeder. The machine has the following different advantages:

1. The double-mass side discharge activation feeder in Hebi coal chemical industry is based on the principle of near resonance, and the number of vibrations per minute is 1000 times. control.

2. The fully sealed structure is adopted, the sealing performance is 100%, there is no dust and water overflow, and the site is clean and environmentally friendly.

3. Advanced dual-mass patented technology, single motor drive, shear rubber spring secondary force transmission, low power consumption, high efficiency, energy saving and power saving. The same feeding amount saves electricity cost (18.5-3.7)*24*365=130,000 yuan a year compared with other models of feeders, and 11 units save about 1.43 million yuan a year in electricity costs. This is net profit.

4. The machine is equipped with an intelligent online monitoring system, which can realize first-level early warning of hidden dangers, timely shutdown of second-level accidents, no need for manual inspection, and save the cost of post workers and inspection workers by 250,000 yuan a year.

5. With the activation function, the coal can transmit the disturbance kinetic energy upward during the operation of the feeder, and there will be no blocking and arching within two meters.

6. Good smash resistance and impact resistance.

7. Advanced dual-mass technology, the maintenance of the whole machine is small, and it is famous for not burning the motor!

8. The whole machine has the coal safety certificate and mine safety certificate certified by the National Safety Standard Center.

9. Safe, environmentally friendly, green, intelligent, and low-maintenance dual-mass side discharge activation feeder, which fully meets the on-site use and the national call requirements. You can use it with confidence.

At present, the container station adopts the side discharge activation feeder produced by Hebi Coal Chemical Machinery Co., Ltd., which is low-consumption, high-efficiency, energy-saving, environmental protection, and small in maintenance. Work is easy from now on! It saves about 1.43 million yuan in electricity bills every year, and can ship more coal with about 200 million yuan in profit each year. Welcome people of insight to inspect and order.