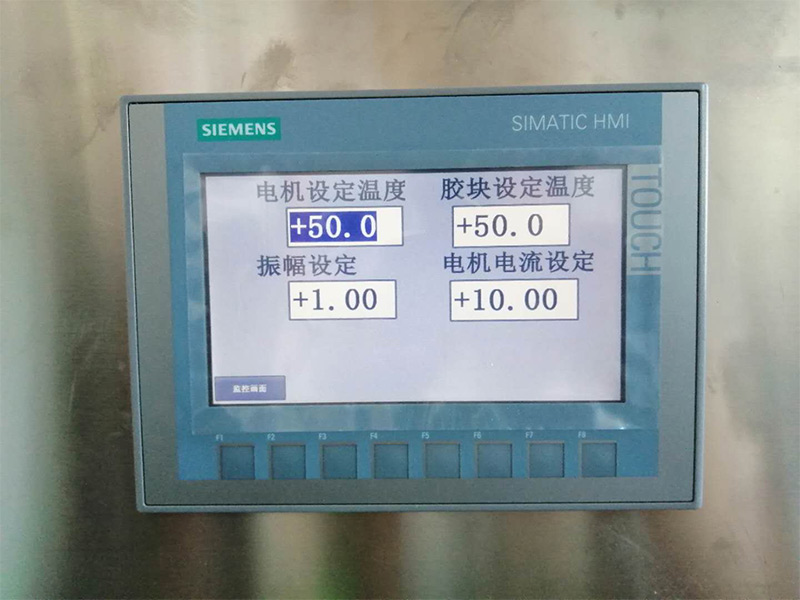

●Real-time intelligent diagnosis information summary function. Equipment temperature acquisition function, vibration frequency, bearing temperature, motor vibration acquisition function, information processing, screen display and transmission function, etc.

● the use of signal recognition and characterization technology, real-time diagnosis of equipment and fault damage location and severity. Early warning and forecast function. The staff can master the running state of the equipment at any time. The system notifies maintenance personnel in time when any abnormality occurs.

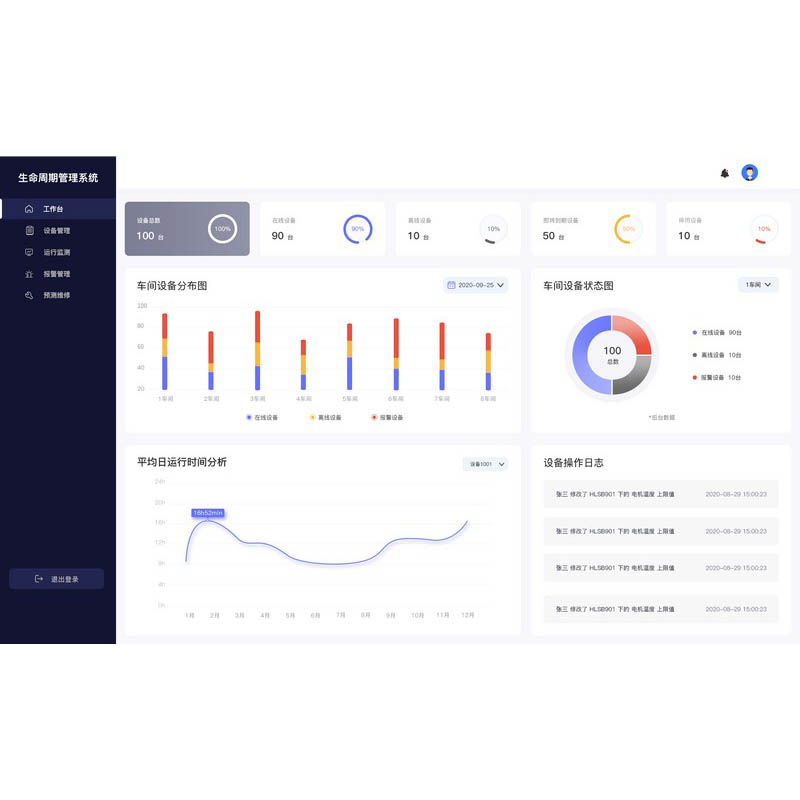

●Historical information query function. It can query daily reports, weekly reports, monthly reports and all alarm records according to user requirements, and conduct data analysis at the same time.

●mobile phone terminal, PC display and remote Web browsing function. By means of network transmission, the data of the system can be transmitted locally and remotely to achieve data sharing and multi-point access.

●Timely find hidden dangers, make maintenance arrangements in advance, and reduce huge losses caused by unplanned shutdown of key equipment.

●Monitor production safety of equipment in real time, reduce labor costs, improve work efficiency of employees, give early warning and stop equipment in advance for slight abnormalities, and reduce the risk of direct equipment damage and scrap.

●Effectively prevent safety accidents, realize remote monitoring, reduce the trouble of workers’ on-site supervision, and the harm of personnel working for a long time under high dust.

●Effectively reduce the cost of equipment after-sales maintenance, facilitate the early detection and early treatment of hidden trouble, so that small problems can be timely dealt with.

●Reduce maintenance spare parts inventory overhang costs. Advance prevention, advance filing, maintenance plan, rectification is in place. Reasonable control of unnecessary expenses will be a considerable net profit.

Transmission subsystem of the Internet of Things: the information data collected and processed by each functional module in the offline information collection and control subsystem can be transmitted to the online monitoring and early warning management subsystem in a real-time, stable and effective manner through wired or wireless mode.

Abnormal information intelligent shutdown protection function: according to customer requirements, with the system to collect information, combined with the management background to set the data threshold range, determine the collected information is abnormal information, intelligent shutdown.

Wireless transmission of vibration frequency acquisition function: It collects vibration frequency information of related vibration production equipment, intelligently determines whether there is abnormal and timely sends warning information to equipment management personnel based on the threshold set in the management background, which can effectively avoid equipment damage caused by abnormal vibration frequency of equipment in the production process.